We focus on ring, packings and valves for reciprocating compressors, just contact us by shanghai.jwu@outlook.com

We focus on ring, packings and valves for reciprocating compressors, just contact us by shanghai.jwu@outlook.com

Shanghai Leah Industries Co., Ltd. is a manufacturing facility in Southwestern Shanghai. All founders graduated from Xi’an Jiaotong University, have extreme good experience in reciprocating compressor engineering, manufacturing, sales, service and management.

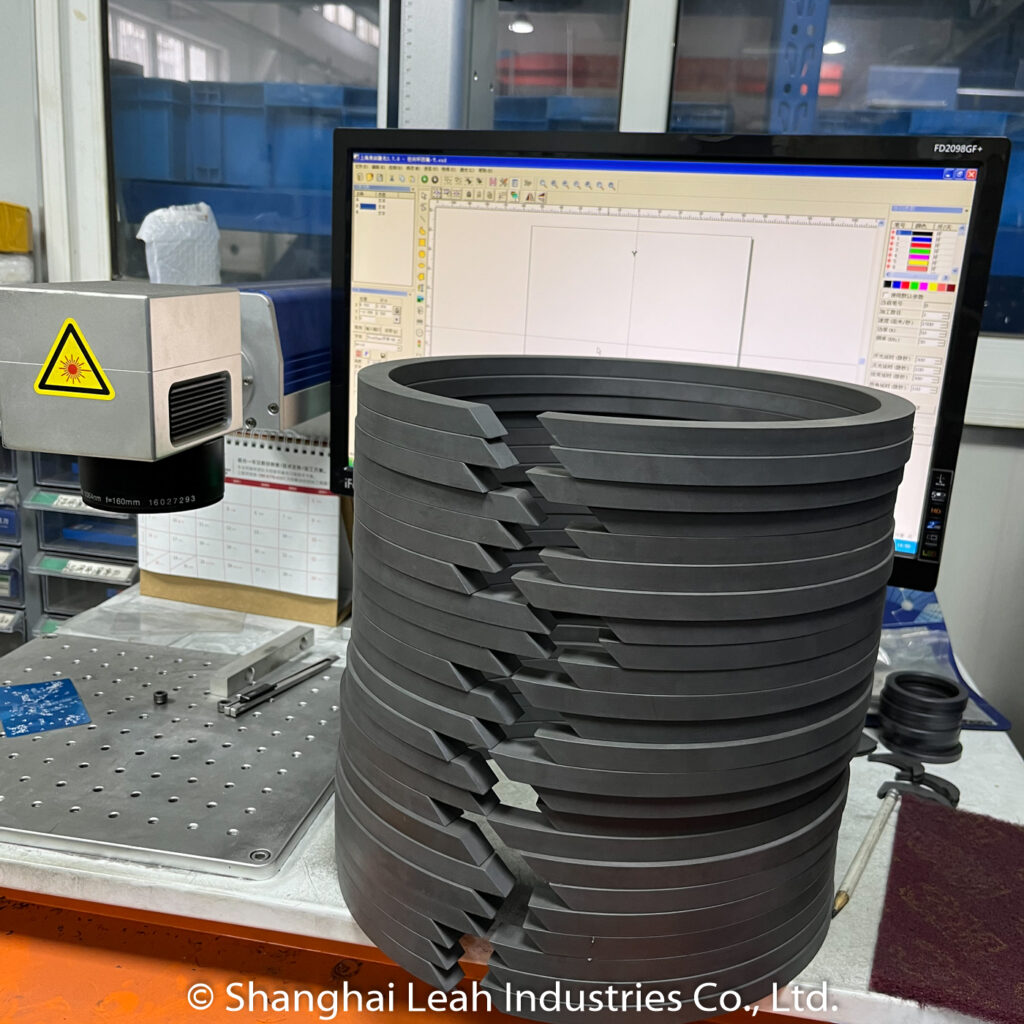

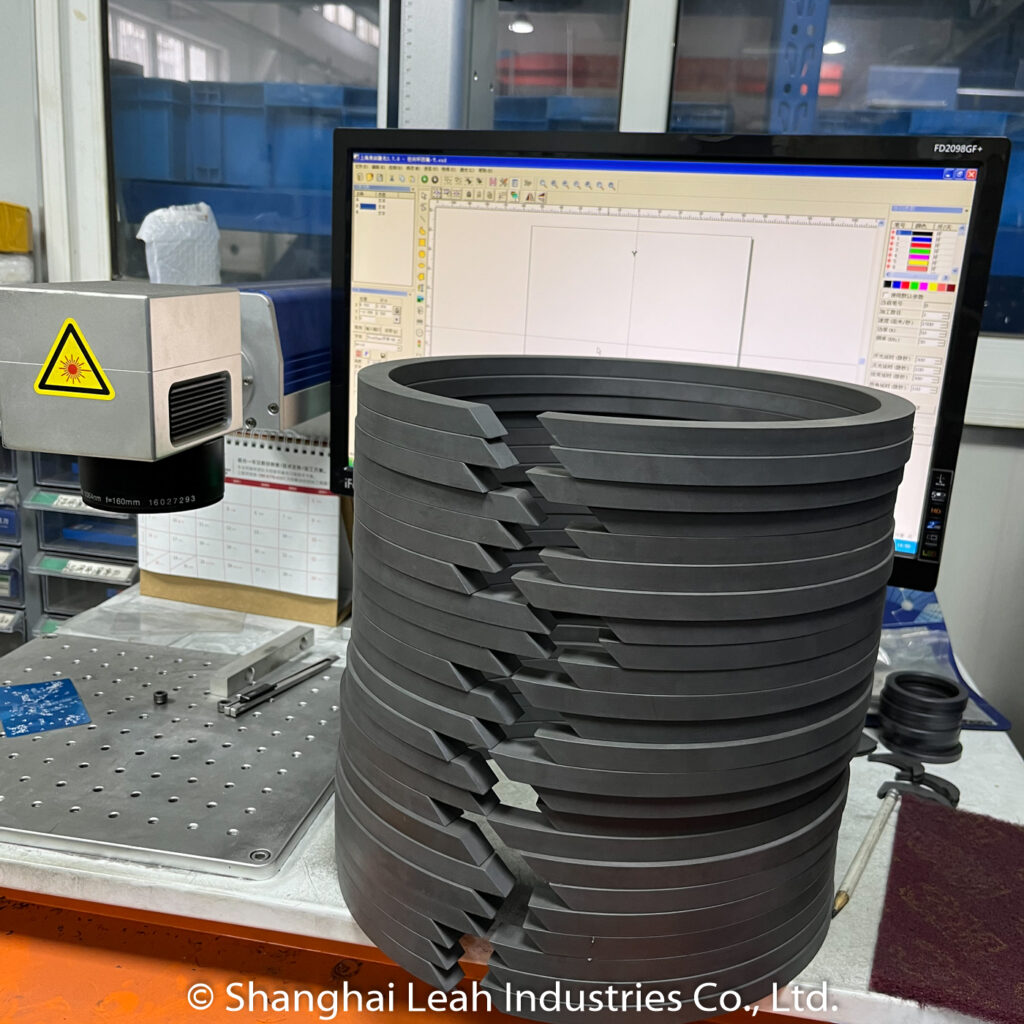

Leah Industries devote to improve the performance of rings, packings, wipers, valves and lubricators – these critical components for reciprocating compressors. Leah Shanghai has own workshop, is able to control quality, decrease cost, increase efficiency, reduce lead time by ourselves completely. Leah high performance materials use mature recipes and procedure, good for Oil & Gas / Petrochemical / CNG / LNG / BOG / PET and other industries.

At Leah we control our materials from the start, which decreases the customer lead time and allows for an efficient manufacturing process. Our capabilities include in-house material blending and testing which enable Leah to develop proprietary blends that fit your individual application needs and enhance the performance of both field and process gas compressors. These in-house capabilities enable us to maintain stringent trace ability controls throughout every stage of manufacturing from compounding materials to finished products, and these records are preserved throughout the product life cycle.

Our expansive portfolio of high-performance polymeric materials combined with on-site engineering and design expertise offers our customers an invaluable resource for transforming advanced engineering materials into high-performance solutions. Our materials portfolio includes an extensive selection of compounds created with the following base resins:

This variety of base resins allows for outstanding performance in environments ranging from natural gas and air to bone-dry process gasses. This wide range of application performance is detailed in the Materials Selection Guide.

Leah’s exceptional Engineering staff combines material, application, and development expertise to create unique solutions for the most demanding industry problems. Our technical staff optimizes the design and manufacturing process by using state-of-the-art programs such as:

Starting with material development and continuing through component design and manufacturing, Leah provides every service under one roof. Leah offers a wide array of traditional and modern machining capabilities to manufacture compressor parts, from short runs to full-scale production. We offer some of the most extensive molding and manufacturing capabilities in the industry, including:

Our manufacturing, design, safety, and quality expertise are backed up by our certifications to ISO 9001-2015, except support local customers in China, we also export to USA, Canada, Mexico, UK, Germany, Spain, Sweden, Brazil, Thailand, Malaysia, Turkey, India, Ukraine, Saudi Araba, UAE, Argentina etc. Liability, Efficiency, Accuracy and Honesty are the driving forces behind the unique solutions provided every day by Leah Compressor Parts. We consistently solve industrial challenges with more than 20 years of experience designing and manufacturing high-performance, non-metallic compressor parts. Supported by specifications with some of the industry’s leading companies and over 30 manufacturing processes, Leah has the extensive experience, modern equipment and the breadth of capabilities to produce high-quality parts that keep your compressors efficient and reliable.

Valuable parters:

Founder profile in LinkedIn: